D

Deleted member 147267

Guest

I think the only thing keeping me sane during lock down is my Little Shop of Horrors. While I wait for more warm weather to spray #1, I have #2 on the go, but I will run out of things to do very soon if I can't shop for materials. I'll just post highlights rather than document a build like I did for Nautical Gent, and will include a few concepts that didn't apply in that build...

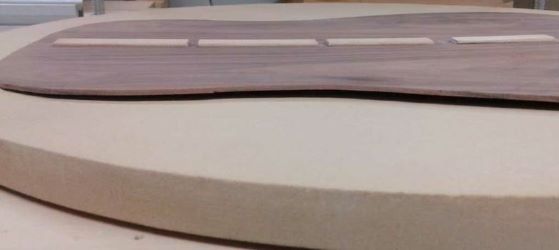

This is a back brace sitting on a radius sanding dish (15 ft radius). The braces are placed in the approximate location that they would be if this was a back and they are sanded until they conform to the arc of that location. Each brace takes on a different arch because the dish arc is not the same near the perimeter as it is in the center. When glued on in a companion radius dish (in the go-bar deck) the back takes on the shape of the arcs.

Note the back plate sitting on the glue-up radius dish, showing the gap. Top and bottom touch the dish but the rest of it, not so much.

Same story for the top, but a 25 ft radius. Some builders do 40 ft but I don't see the point in that.

.

.

If you saw the Uke thread, you saw in top and back glue up before. The uke back was not arched (too small).

.

.

.

.

One needs lots of clamps to glue up kerfing on 2 sides at once!

.

.

Headstock plate & rough carved heel.

.

.

This is a back brace sitting on a radius sanding dish (15 ft radius). The braces are placed in the approximate location that they would be if this was a back and they are sanded until they conform to the arc of that location. Each brace takes on a different arch because the dish arc is not the same near the perimeter as it is in the center. When glued on in a companion radius dish (in the go-bar deck) the back takes on the shape of the arcs.

Note the back plate sitting on the glue-up radius dish, showing the gap. Top and bottom touch the dish but the rest of it, not so much.

Same story for the top, but a 25 ft radius. Some builders do 40 ft but I don't see the point in that.

If you saw the Uke thread, you saw in top and back glue up before. The uke back was not arched (too small).

One needs lots of clamps to glue up kerfing on 2 sides at once!

Headstock plate & rough carved heel.

Last edited by a moderator: