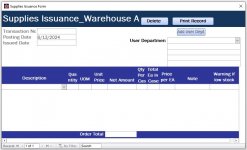

Now I am thinking how can I modify my database while it is already go live. This is my input form for supplies out. To indicate warehouse, I should add the field in the sub form at the very left inventory sub form?.

But I still be having a problem on the quantity type. I think that should be a field for the basis unit of measure which is EA. Whether we sell or receive should start everything from EA then there is a conversion field to arrive at used Unit of Measure (Case) or in EA in case we receive or sell the supplies.

I appreciate any help or giving a sample database

Thank you

Frank

Only make changes and test the changes in a non-production database.

I hope you considered the advice in post #17 ? The aim is to have just one consolidated database.

Step 1: Figure out what you need to do to make the Product tables consistent in both Warehouse databases and make a universal product table for implementation in the one database. Make a detailed plan. What are the steps, timings, needs, conditions for doing it.

- Extract data from each database into a test database containing all records from each Product table. It must have the ProductID, WarehouseCode, ProductCODE (if available), ProductDesc, .... and a column for Matchedto (the to hold the Productt ID for the match)

- 2 queries one for Warehouse A one for B, showing the list of products, in ProductCODE order, or Product Description Order. Compare/eyeball the two lists for matching. If it matches up well, you can apply an update query to mark the Product record from Warehouse B that matches to the Product for Warehouse A (place the Product ID from Warehouse A in MatchedTo for Products from Warehouse B).

You might find near matches which should match but the Description does not quite align. Perhaps you might get the Product description changed in the PROD database so that when this process is repeated it does match.

You will likely have leftovers. That may require further (manual) effort. You might consider a Checked column to keep track of which records have been reviewed - update via the query and for those eyeballed and OK with or with no corresponding record. However I would expect that all your records should have a match however there may be items that are accepted and sold from Warehouse B or only within Warehouse A.

- This is a test. When you are satisfied with your procedures - and you should document them - you will need to run them against a fresh copy of the Production system AGAIN, check again. When you are confident you have the data in a good state - remembering that it must be suitable for your existing purchase and sales records - then you are ready to apply it finally to your new consolidated database - and have users swap to that - provided you have also prepared the front end for that change. (You cannot afford to support three databases - any further additions/deletions, mods to the Product Table in either warehouse needs to be reflected in the universal table. However you need to develop and design the consolidated database application which will incorporate the universal product table ensuring that your inventory controls work against the universal product table.

- That also means you need to have some users Test your consolidation and updated database inventory/sales/purchases before going to production.

Re SKU / ProdCODE - if you do not have this already you also need to work on this too as you complete/ develop and test your universal product table. Do your suppliers have an SKU or ProductCode marked on their products? (see again post 17 and the StockUnits table: it can handle what you receive in cases and can translate these to units for stocktake purposes.

There are many wrinkles in the process of migrating the data: what will you do about the historical Purchase and Sales records pointing to the old ProdID when using the new universal Product Table? The values are in the proposed table but you may need to consider an update to those. Reports for Sales and Purchases also need adjustment (including ones which span the changeover date).

Do not forget back up of both databases immediately prior to changeover.