RickDB

Registered User.

- Local time

- Today, 05:10

- Joined

- Jun 29, 2006

- Messages

- 101

My database uses a common structure (from what I understand):

tblCustomers

tblOrders

tblOrderDetails

so, when an item is entered in, the following is recorded (the field names may not be right, but you 'll get the effect):

tbOrders:

TaxRate

ShippingCost

tblOrderDetails:

Quantity

ModelName

Price

Calculated totals on the form/reports:

Extension (line price for each order detail)

SubTotal (Sum of Extensions)

Taxes

Total

So I have struggled and finally made this work, but here is the problem:

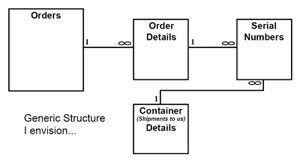

Say I want to record the serial number for each product sold. What is a good method to do this? Obviously I cannot store it in the OrderDetails table because each line/entry could account for any quantity of that model.

I know a one to many is required, has anyone done this before and can you spare some advice? I want to make sure I get the structure right because I will have to alter a significant amount of my database to implement this feature.

Thank you!!!!

tblCustomers

tblOrders

tblOrderDetails

so, when an item is entered in, the following is recorded (the field names may not be right, but you 'll get the effect):

tbOrders:

TaxRate

ShippingCost

tblOrderDetails:

Quantity

ModelName

Price

Calculated totals on the form/reports:

Extension (line price for each order detail)

SubTotal (Sum of Extensions)

Taxes

Total

So I have struggled and finally made this work, but here is the problem:

Say I want to record the serial number for each product sold. What is a good method to do this? Obviously I cannot store it in the OrderDetails table because each line/entry could account for any quantity of that model.

I know a one to many is required, has anyone done this before and can you spare some advice? I want to make sure I get the structure right because I will have to alter a significant amount of my database to implement this feature.

Thank you!!!!