MajP

You've got your good things, and you've got mine.

- Local time

- Today, 15:07

- Joined

- May 21, 2018

- Messages

- 10,018

I can demo this if I can decipher it.

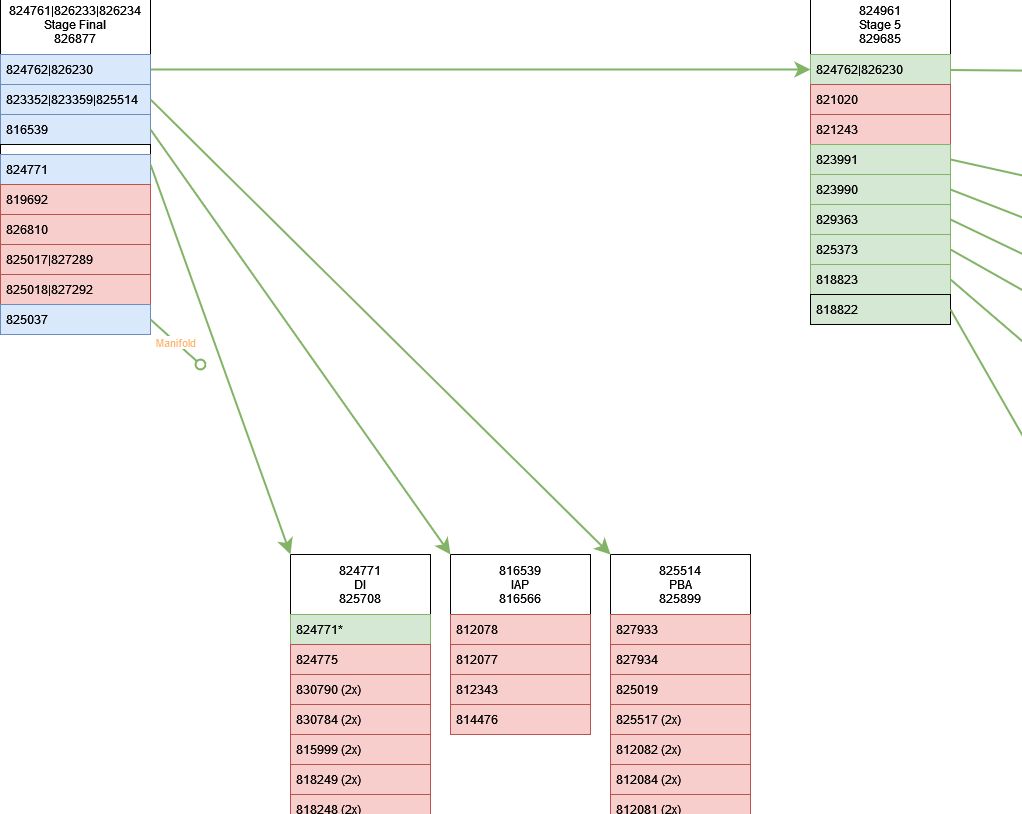

Here is a cut away section to try to get some clarity.

Questions:

1. Is "Stage Final" the name of the top level Assembly?

2. There are three part numbers above the word Stage Final. Does this represent three different top level assembles or why three numbers?

3. Below "Stage 3" is one number is that the document number for a top level assembly

4. The first blue box has two numbers again. Why two numbers?

5. 824762/826230 flows into Stage 5 but I do not understand this. Stage 5 (the white box) is what I though was a subassembly of Stage Final. I would think the first green box was a sub assembly of Stage 5.

6. PBA 825514 appears to be a subassembly of Stage Final ( so are DI, IAP). But the blue box in Stage Final has three numbers. How do you interpret the other two numbers?

7. Just to be sure at this points these are all part numbers, but at a later date you would assign specific serial numbers to each part? There are no serial numbers in this view?

Here is a cut away section to try to get some clarity.

Each box is an assembly of serialized parts.

The header contains: Assembly Part Number, Assembly Name, Record Document Part Number

Below the header is the list of serialized components that make up the assembly.

Red - Serialized part with no sub components.

Blue - Assembly with serialized sub components.

Green - Assembly with serialized sub components. (But there is no input on the record to make the relationship, this is for my management.)

Questions:

1. Is "Stage Final" the name of the top level Assembly?

2. There are three part numbers above the word Stage Final. Does this represent three different top level assembles or why three numbers?

3. Below "Stage 3" is one number is that the document number for a top level assembly

4. The first blue box has two numbers again. Why two numbers?

5. 824762/826230 flows into Stage 5 but I do not understand this. Stage 5 (the white box) is what I though was a subassembly of Stage Final. I would think the first green box was a sub assembly of Stage 5.

6. PBA 825514 appears to be a subassembly of Stage Final ( so are DI, IAP). But the blue box in Stage Final has three numbers. How do you interpret the other two numbers?

7. Just to be sure at this points these are all part numbers, but at a later date you would assign specific serial numbers to each part? There are no serial numbers in this view?

Last edited: