Hi All,

I'm fairly new to access, and I've run into an issue and I'm not sure the best way to proceed.

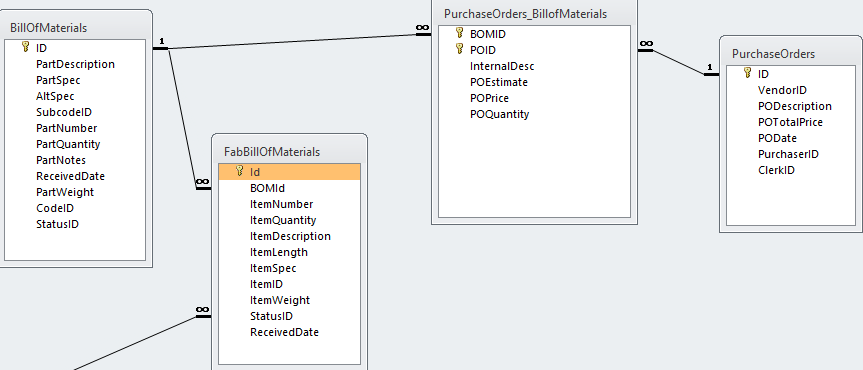

I have a many-to-many relationship between two tables (BillOfMaterials and PurchaseOrders) with a join table (PurchaseOrders_BillOfMaterials). I have a second table (FabBillOfMaterials) that also has a many-to-many relationship with the PurchaseOrders Table. Is there a way to use the same join table for both relationships (BOM to PO and FabBOM to PO) or is it best practice to make another join table?

I'm fairly new to access, and I've run into an issue and I'm not sure the best way to proceed.

I have a many-to-many relationship between two tables (BillOfMaterials and PurchaseOrders) with a join table (PurchaseOrders_BillOfMaterials). I have a second table (FabBillOfMaterials) that also has a many-to-many relationship with the PurchaseOrders Table. Is there a way to use the same join table for both relationships (BOM to PO and FabBOM to PO) or is it best practice to make another join table?