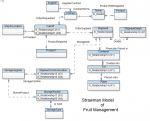

Nick --Fruit Management --CallOffContracts.

Draft rules: (these are preliminary and need to be refined and vetted)

Our company deals with many Suppliers

Many Contract(s) are set up with a Supplier

A Contract defines the Products and Quantities to be Supplied (other Terms/conditions?). No other relevant Terms and Conditions

A CallOff is a PurchaseOrder against an active Contract. The Purchase Order is the contract - for the purposes of this database the Supplier has agreed the contract and the PO is in place for product to be called off against it.

Many PurchaseOrder(s)/CallOff(s) may be placed against a Contract with Supplier

A PurchaseOrder may be for a proposed Quantity of 1 or Many Product(s)

A PurchaseOrder identifies the ShipTo Location. YES

A Supplier ships many Product(s) as a Shipment

A Shipment has many ShipmentDetails

A Shipment identifies the actual shipped Quantity of Product. YES

A Shipment identifies the Container holding the Product. YES

A Container hold MANY Lots/Batches of shipped Product

A Shipment identifies the BestBeforeDate of each Lot of shipped Quantity of Product. YES

The PO proposed quantity of Product may differ from the actual shipped quantity of Product. YES - some unit quantities vary e.g drums of pulp will have different weights say +/- 5kg

The actual shipped quantity of Product is subtracted from the Contracted quantity. YES

A Lot(Batch) is a quantity of shipped Product with a common ProductType and BestBeforeDate. YES

A Shipment is separated into 1 or more Lot(s) based on ProductType and BestBeforeDate (by whom?) ME - The loading documents from the supplier have the information, I enter the data and a unique [incremental] Lot No is created.

A Shipment may contain 1 or many Pallets

A Pallet may contain 1 or Many Lots. Usually 1 and should be 1 but does happen occasionally

Draft rules: (these are preliminary and need to be refined and vetted)

Our company deals with many Suppliers

Many Contract(s) are set up with a Supplier

A Contract defines the Products and Quantities to be Supplied (other Terms/conditions?). No other relevant Terms and Conditions

A CallOff is a PurchaseOrder against an active Contract. The Purchase Order is the contract - for the purposes of this database the Supplier has agreed the contract and the PO is in place for product to be called off against it.

Many PurchaseOrder(s)/CallOff(s) may be placed against a Contract with Supplier

A PurchaseOrder may be for a proposed Quantity of 1 or Many Product(s)

A PurchaseOrder identifies the ShipTo Location. YES

A Supplier ships many Product(s) as a Shipment

A Shipment has many ShipmentDetails

A Shipment identifies the actual shipped Quantity of Product. YES

A Shipment identifies the Container holding the Product. YES

A Container hold MANY Lots/Batches of shipped Product

A Shipment identifies the BestBeforeDate of each Lot of shipped Quantity of Product. YES

The PO proposed quantity of Product may differ from the actual shipped quantity of Product. YES - some unit quantities vary e.g drums of pulp will have different weights say +/- 5kg

The actual shipped quantity of Product is subtracted from the Contracted quantity. YES

A Lot(Batch) is a quantity of shipped Product with a common ProductType and BestBeforeDate. YES

A Shipment is separated into 1 or more Lot(s) based on ProductType and BestBeforeDate (by whom?) ME - The loading documents from the supplier have the information, I enter the data and a unique [incremental] Lot No is created.

A Shipment may contain 1 or many Pallets

A Pallet may contain 1 or Many Lots. Usually 1 and should be 1 but does happen occasionally