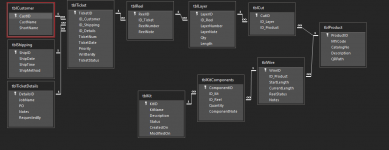

I am revisiting a backend I made about 2 years ago at this point and trying to making improvements as I know a lot more than I did then and the old design isn't playing well with converting to a Python based front end. I have attached a picture of it. This is the backend for an application that facilitates the sending of request to our wire room to be cut as well as manages their inventory at a rudimentary level as our primary POS system doesn't provide the granular level we need for said inventory.

I have already done work in reworking several of the tables and splitting them apart a bit more, such as removing shipping details from tblTicket and other odds and ends. The main issue I am having is how to reconcile the tables tblWireCut, tblColorWire and tblCutColorWire as the first two pretty similar. The reason for the initial separation was I could not figure out how to handle reels containing multiple product at various length while also keeping a straight forward method for doing a typical one product request such as 3x50'.

How would I restructure the tables to handle essentially a container that can contain multiple types of product and various lengths? A single reel could potentially have 12 different products and 4 different lengths. Think of a giant wire spool that has 4 different color wire at one length stacked on top of another 4 set of various color wire at a different length and so on.

My initial thought was to eliminate tblColorWire and tblCutColorWire completely and place a new table between tblTicket and tblWirecut to facilitate this "container" that could have one item or many.

I have already done work in reworking several of the tables and splitting them apart a bit more, such as removing shipping details from tblTicket and other odds and ends. The main issue I am having is how to reconcile the tables tblWireCut, tblColorWire and tblCutColorWire as the first two pretty similar. The reason for the initial separation was I could not figure out how to handle reels containing multiple product at various length while also keeping a straight forward method for doing a typical one product request such as 3x50'.

How would I restructure the tables to handle essentially a container that can contain multiple types of product and various lengths? A single reel could potentially have 12 different products and 4 different lengths. Think of a giant wire spool that has 4 different color wire at one length stacked on top of another 4 set of various color wire at a different length and so on.

My initial thought was to eliminate tblColorWire and tblCutColorWire completely and place a new table between tblTicket and tblWirecut to facilitate this "container" that could have one item or many.