You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D

Deleted member 147267

Guest

If it wasn't bad enough that The Doc Man has us googling words, Micron has us googling tools.

Worked all day, doesn't seem like I accomplished much.

I trimmed the back close to the sides and installed the kerfing for the top. I'll flush trim the back when the side is on so that I can do both with one tool setup.

To get the top on, I at least have to create the sound hole because the top wouldn't lay flat if the braces were on. However, just a sound hole would be too simple. Here's my plan for a simple rosette that I laid out with a compass. The wood strips are 0.032" thick and will be going into circular slots...

and the palm sized router on my circle cutting jig.

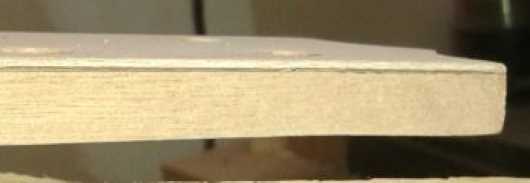

Part of this glue up has to set overnight, so I decided to make the bridge from Black Walnut (80mm x 25mm x 54mm high).

Looks bigger/thicker in the picture than it really is, I think, because that thin edge is only 2mm thick. The left slot is for the saddle.

Will have to figure out where the holes go for the strings.

Back to the top tomorrow.

- Local time

- Today, 14:33

- Joined

- Feb 28, 2001

- Messages

- 30,554

I'm watching this but avoiding too many comments. Let me say this, though: My dad would have been fascinated to see this. He sometimes made balsa-wood scale models for a 3D rendition of architect's plans. He did that two or three times for Jefferson Parish to show what a particular building would look like if it were built. He even made it to match one of the smaller model railroad scales so that he could put a couple of people and a couple of cars in the model to provide size references. This was before it was possible to make a virtual image based on plans. I think he would approve of what you have shown us.

AccessBlaster

Be careful what you wish for

- Local time

- Today, 12:33

- Joined

- May 22, 2010

- Messages

- 7,579

Awesome series.

D

Deleted member 147267

Guest

Thank You!Awesome series.

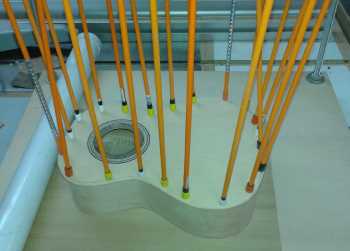

Will post pics tomorrow as there isn't a whole lot of interesting stuff tonight. I have the top in the go-bar deck, gluing the top braces on. Looks like a forest of bamboo under there!

The circle cutting jig I showed above is meant for full size sound holes (for guitars, not ukes). I had to modify it to get down to the 2" range I need for a uke, but that caused issues that bedeviled me all day yesterday and most of today. The majority of the time on that part of the job was waiting for glue to set enough that I could safely work the piece with hand tools. Long story short, I'm going to have to lengthen the pivot pin because it's too short for this kind of work, but I'll have a challenge because it's epoxied in place. Unfortunately this issue allowed things to move around a bit, so I had to keep changing the design plan to fix screw-ups, and the screw-ups usually involved wood and glue as a remedy.

I tried bending African Mahogany binding tonight but they all broke. Seems each species has their own requirements and the learning curve is trial and error. Usually I rely on Google to cut down the rate of errors, but I guess this time I incorrectly figured that since it was such a low density wood that the usual 295 degrees would do the trick. WRONG! Google, here I come again....

D

Deleted member 147267

Guest

The following post contains images of extreme toolage. Viewer discretion is advised....

Well I tried 5 times to bend African Mahogany for binding by using various temperatures and techniques but no luck. I even brought out the heavy artillery for the 4th and 5th tries - the steam box! Alas, every set cracked; some of them badly. I guess when this species is so narrow (2mm) there just isn't enough meat there to make the grain hold together.

..

..

Meanwhile, the rosette is done and here we have the top in the go-bar deck to glue the braces on. In the finished view you might be able to see that there is a linen patch that adds strength (glue soaked cloth). I'm not sure that it's a common technique anymore as it hails from the old days.

. .

. .

Last pic is the top being glued on.

Tomorrow I will see if my last attempt to bend binding was successful or not after leaving it in the bender overnight to cool and set. I gave up on the Mahogany and switched to Black Walnut and I didn't hear any cracking, so fingers crossed!

Well I tried 5 times to bend African Mahogany for binding by using various temperatures and techniques but no luck. I even brought out the heavy artillery for the 4th and 5th tries - the steam box! Alas, every set cracked; some of them badly. I guess when this species is so narrow (2mm) there just isn't enough meat there to make the grain hold together.

Meanwhile, the rosette is done and here we have the top in the go-bar deck to glue the braces on. In the finished view you might be able to see that there is a linen patch that adds strength (glue soaked cloth). I'm not sure that it's a common technique anymore as it hails from the old days.

Last pic is the top being glued on.

Tomorrow I will see if my last attempt to bend binding was successful or not after leaving it in the bender overnight to cool and set. I gave up on the Mahogany and switched to Black Walnut and I didn't hear any cracking, so fingers crossed!

D

Deleted member 147267

Guest

Black Walnut is a breeze to bend - so that's what this is getting for binding. I mentioned elsewhere that I had a few spare parts from a kit, and one of them was a neck. Check out this off center factory located placement of the dowel pins for joining to the head block. I filled them with hardwood dowel and relocate them.

Decided to add a headstock plate of Black Walnut; here's where I marked off 1/16th of an inch to take off, then glue a plate on that's equal to the thickness that is removed. This plate will be visible in the next pic.

I have no fret wire, strings or tuners, which will be a problem because of this Covid thing, but here's how it's looking right now. The fret board is just taped on for this pic because it's easier to install fret wire before gluing the fret board on. The bridge is also just taped on because it doesn't get located until the fret board is installed permanently. You can see the headstock plate in this pic - looks better than just plain mahogany I think. Hopefully the Black Walnut binding will 'pop' a bit more when a finish is applied.

A view of the back side. I have a Black Walnut heel cap roughed out which will go on when the neck has been fixed in position (arrow points to location). The heel is the part of the neck where it meets the body at the bottom. Some are flush with the back, some lower. This one will probably be flush.

Well, I have to see what I can do about my missing materials without going crazy over pricing. This Covid thing has knocked the crap out of the Canadian dollar, so anything that I order from US will cost me about 45% more just for the material, then duties and import fees on top of the converted cost if the items are not made in U.S. . Bad enough that this is done at all, but after the dollar conversion? It adds insult to injury. I will have to look for a more local supply, but forget about going out to get it as non-essential businesses were mandated to close today until further notice.

Decided to add a headstock plate of Black Walnut; here's where I marked off 1/16th of an inch to take off, then glue a plate on that's equal to the thickness that is removed. This plate will be visible in the next pic.

I have no fret wire, strings or tuners, which will be a problem because of this Covid thing, but here's how it's looking right now. The fret board is just taped on for this pic because it's easier to install fret wire before gluing the fret board on. The bridge is also just taped on because it doesn't get located until the fret board is installed permanently. You can see the headstock plate in this pic - looks better than just plain mahogany I think. Hopefully the Black Walnut binding will 'pop' a bit more when a finish is applied.

A view of the back side. I have a Black Walnut heel cap roughed out which will go on when the neck has been fixed in position (arrow points to location). The heel is the part of the neck where it meets the body at the bottom. Some are flush with the back, some lower. This one will probably be flush.

Well, I have to see what I can do about my missing materials without going crazy over pricing. This Covid thing has knocked the crap out of the Canadian dollar, so anything that I order from US will cost me about 45% more just for the material, then duties and import fees on top of the converted cost if the items are not made in U.S. . Bad enough that this is done at all, but after the dollar conversion? It adds insult to injury. I will have to look for a more local supply, but forget about going out to get it as non-essential businesses were mandated to close today until further notice.

NauticalGent

Ignore List Poster Boy

- Local time

- Today, 15:33

- Joined

- Apr 27, 2015

- Messages

- 6,872

Looking good Micron!! I sent you an email about a possible logistics work-around...

AccessBlaster

Be careful what you wish for

- Local time

- Today, 12:33

- Joined

- May 22, 2010

- Messages

- 7,579

One badass Ukulele! Maybe a video demo when finished? Do you also make acoustic guitars?

isladogs

Access MVP / VIP

- Local time

- Today, 20:33

- Joined

- Jan 14, 2017

- Messages

- 19,326

It really looks stunning. You make my woodworking skills look feeble by comparison.

I look forward to each new update that you post and am learning lots from this thread.

Perhaps serenade us all when it is finished...

I look forward to each new update that you post and am learning lots from this thread.

Perhaps serenade us all when it is finished...

NauticalGent

Ignore List Poster Boy

- Local time

- Today, 15:33

- Joined

- Apr 27, 2015

- Messages

- 6,872

I hope that was meant for Micron and not me. I have blessed with the ability to retain useless facts about music and I'll wager I know more lyrics and their meanings than the vast majority of people. That ability comes with a price...I couldn't carry a tune in a bucket...Perhaps serenade us all when it is finished...

- Local time

- Today, 14:33

- Joined

- Feb 28, 2001

- Messages

- 30,554

I can relate, Gent. My fingers can play stuff from Bach to the Beatles, but I can't carry a tune in a #5 washtub.

D

Deleted member 147267

Guest

Thanks for the compliments. I'm not a uke player, so I will leave it to NG to play it for us when he gets it! Maybe even one of his grandkids could learn to play a tune and then he can upload that. But who knows, maybe I will come up with something along that line . My issue is that I know where to put my fingers for D chord on a guitar for example, but on a uke it's totally foreign to me so I'd stumble for sure.

As for guitars, sort of. There are some pics in the [thread name removed] thread ( I think ) of one that I'm working on. I've started another and have another set of tonewood waiting for me after that. I wouldn't call myself a luthier though as I think you'd have to build at least 5 or 6 before you could make that claim. The reason for starting one when the first is unfinished is because I want to spray on the final finishes but can't really do that until it warms up because I don't have a heated spray booth and it's too cold here to risk it right now.

I thought about posting pics of the new build as a thread, but then that's not really what this forum is for I guess, and I'm not sure I want to bother joining a luthier forum just so I can do that.

I will post some new pics soon because the fret wire and tuners showed up yesterday, much to my surprise. I have installed the frets, glued on the fretboard and brushed on a sealer coat onto the neck and body. All I'm waiting for now is the strings. Looking good to me!

As for guitars, sort of. There are some pics in the [thread name removed] thread ( I think ) of one that I'm working on. I've started another and have another set of tonewood waiting for me after that. I wouldn't call myself a luthier though as I think you'd have to build at least 5 or 6 before you could make that claim. The reason for starting one when the first is unfinished is because I want to spray on the final finishes but can't really do that until it warms up because I don't have a heated spray booth and it's too cold here to risk it right now.

I thought about posting pics of the new build as a thread, but then that's not really what this forum is for I guess, and I'm not sure I want to bother joining a luthier forum just so I can do that.

I will post some new pics soon because the fret wire and tuners showed up yesterday, much to my surprise. I have installed the frets, glued on the fretboard and brushed on a sealer coat onto the neck and body. All I'm waiting for now is the strings. Looking good to me!

Last edited by a moderator:

isladogs

Access MVP / VIP

- Local time

- Today, 20:33

- Joined

- Jan 14, 2017

- Messages

- 19,326

That's an illusion shattered. I thought you had led the crowds singing from the balconies in NaplesI hope that was meant for Micron and not me. I have blessed with the ability to retain useless facts about music and I'll wager I know more lyrics and their meanings than the vast majority of people. That ability comes with a price...I couldn't carry a tune in a bucket...

D

Deleted member 147267

Guest

Fret wire installed, here is a pic of the side dot markers going in to 1/8" drilled holes. The rod sticking up is the last one to be cut for this side. Not a lot of room for error on a uke fretboard!

Fretboard is installed, neck is on and I have applied several coats of finish to the whole thing. I think I have it as best as I'll be able to get. Not factory perfect, but pretty good. It has been warm enough to spray in the garage, then I bring it into my little shop to dry.

The bridge has to be glued on next. I had a clamp that I fabricated for the last uke, but I cannibalized the flat bar portion of it to make a permanent scale tool for locating frets and bridges, etc. so now I have decided to fabricate something more permanent. It needs to be able to reach from the sound hole to where the bridge is to be located. I have much deeper clamps for guitars for this, but there's no way they'll fit into a uke body. This will probably take me the rest of the time I have left for today, so perhaps I can post a pic of the bridge being glued on tomorrow at the latest.

Fretboard is installed, neck is on and I have applied several coats of finish to the whole thing. I think I have it as best as I'll be able to get. Not factory perfect, but pretty good. It has been warm enough to spray in the garage, then I bring it into my little shop to dry.

The bridge has to be glued on next. I had a clamp that I fabricated for the last uke, but I cannibalized the flat bar portion of it to make a permanent scale tool for locating frets and bridges, etc. so now I have decided to fabricate something more permanent. It needs to be able to reach from the sound hole to where the bridge is to be located. I have much deeper clamps for guitars for this, but there's no way they'll fit into a uke body. This will probably take me the rest of the time I have left for today, so perhaps I can post a pic of the bridge being glued on tomorrow at the latest.

AccessBlaster

Be careful what you wish for

- Local time

- Today, 12:33

- Joined

- May 22, 2010

- Messages

- 7,579

Your next project should be on YouTube with voice over.

moke123

AWF VIP

- Local time

- Today, 15:33

- Joined

- Jan 11, 2013

- Messages

- 4,751

Agreed. I'll subscribe!Your next project should be on YouTube with voice over.

- Local time

- Today, 15:33

- Joined

- Jan 23, 2006

- Messages

- 15,498

10-4!Your next project should be on YouTube with voice over.

Similar threads

- Replies

- 37

- Views

- 4,376

- Replies

- 46

- Views

- 4,739

- Replies

- 15

- Views

- 1,910

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)