Ramnik

Registered User.

- Local time

- Today, 18:41

- Joined

- Jul 12, 2012

- Messages

- 145

Hello Everyone,

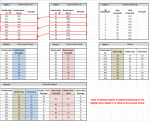

I have a production database in which orders are checked for shortages at different levels of production in which :

1 raw product can be fetched in 2 or more final products,

Shortages are checked as per priority.

Please see attached image for illustration.

In this database i have tables named "finalproductlist" and "rawproductslist" in which products are connected in one to many (see table "productmapping"). For E.g. 1 product in raw table can be fetched into 2 or more final products.

I have stocks query on both levels with which shortage is checked.

I want to create the order shortage query which gives the shortage at both levels prioritywise.

Please help

I have a production database in which orders are checked for shortages at different levels of production in which :

1 raw product can be fetched in 2 or more final products,

Shortages are checked as per priority.

Please see attached image for illustration.

In this database i have tables named "finalproductlist" and "rawproductslist" in which products are connected in one to many (see table "productmapping"). For E.g. 1 product in raw table can be fetched into 2 or more final products.

I have stocks query on both levels with which shortage is checked.

I want to create the order shortage query which gives the shortage at both levels prioritywise.

Please help