i have hit a problem and i am not sure how to get out of it

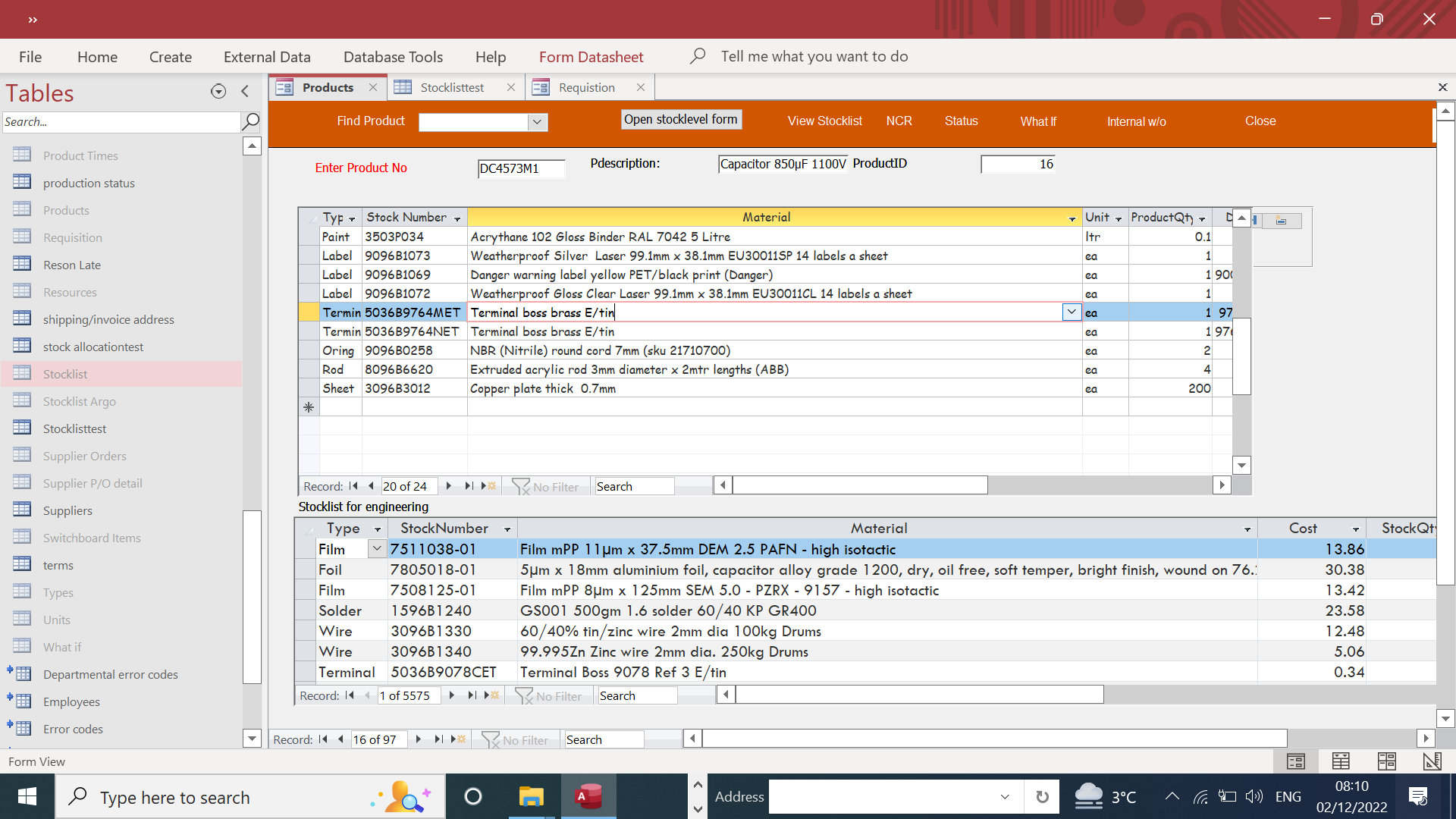

below is a parts list for a product called.DC4573M1 this is a capacitor. if an order arrives for one of these i run a query that looks at the stock for these items and if any need ordering it will show me

the problem i have hit is take this item below from the list above i thought we would just buy this item complete. of which i am now being told mauybe we will want to buy the material ourselfs machine the parts and then send the out for plating

it consists of a procedure of

1. buy raw material say 3 mtrs

2 make bosses out of raw material say 20

3 electrically tin the boss say the same 20

not calling up 40 to be made

thanks steve

Product details Subform Product details Subform

below is a parts list for a product called.DC4573M1 this is a capacitor. if an order arrives for one of these i run a query that looks at the stock for these items and if any need ordering it will show me

the problem i have hit is take this item below from the list above i thought we would just buy this item complete. of which i am now being told mauybe we will want to buy the material ourselfs machine the parts and then send the out for plating

it consists of a procedure of

1. buy raw material say 3 mtrs

2 make bosses out of raw material say 20

3 electrically tin the boss say the same 20

not calling up 40 to be made

thanks steve

Product details Subform Product details Subform

| Type | Stock Number | Material | Unit | ProductQty | DrawingNo | not reqd |

|---|---|---|---|---|---|---|

| Terminal | 5036B9764MET | Terminal boss brass E/tin | ea | 1 | 9764 ref 13 | 0 |